Air quality monitoring is crucial in industrial, commercial, and residential settings, especially in regions like the UAE, where environmental factors and industrial growth contribute to potential air pollution. Gas detection tubes offer a reliable and cost-effective method to measure the presence of harmful gases in the air. These tubes provide quick and accurate readings without requiring complex electronic devices. Understanding how gas detection tubes work, their benefits, and their applications can help industries and individuals ensure a safe working environment.

Gas detection tubes are widely used in various sectors, including oil and gas, chemical manufacturing, and indoor air quality assessment. They are essential for detecting hazardous gases such as carbon monoxide, ammonia, hydrogen sulfide, and volatile organic compounds. The simplicity of their operation and their ability to provide on-the-spot results make them a preferred choice for many professionals in the UAE. In this guide, we will explore the working principle of gas detection tubes, their advantages, and their applications across different industries.

What Are Gas Detection Tubes?

Gas detection tubes are colorimetric devices designed to measure gas concentrations in the air. These glass tubes contain chemical reagents that react with specific gases, changing color to indicate gas presence and concentration levels. They provide a visual indication, making them easy to use and interpret.

Unlike electronic gas detectors, gas detection tubes do not require batteries or calibration. They are ideal for environments where quick, on-the-spot gas measurement is needed. Their reliability and simplicity make them a valuable tool for professionals working in hazardous conditions.

How Do Gas Detection Tubes Work?

Gas detection tubes operate based on a chemical reaction principle. When air is drawn through the tube using a manual or automatic pump, the gas inside reacts with the chemical reagent, producing a color change. The length and intensity of this color change indicate the gas concentration.

Step-by-Step Process:

- Select the Appropriate Tube: Different gases require specific tubes. Choose the tube based on the gas you need to measure.

- Break the Tube Seals: Most tubes are sealed at both ends. These seals need to be broken before use.

- Attach to the Pump: Insert the tube into a gas sampling pump, ensuring a secure connection.

- Draw Air Through the Tube: The pump pulls a fixed volume of air through the tube, allowing the gas to react with the reagent.

- Observe the Color Change: The reaction produces a visible color change along a calibrated scale.

- Determine the Concentration: Compare the color change with the measurement scale printed on the tube to assess gas levels.

Benefits of Gas Detection Tubes

1. High Accuracy and Reliability

Gas detection tubes provide precise measurements with minimal error. They are widely used for occupational safety and industrial hygiene due to their proven reliability.

2. Cost-Effective Solution

Unlike advanced electronic gas detectors, detection tubes are more affordable and require no ongoing maintenance or calibration.

3. Easy to Use

With a straightforward operation, gas detection tubes do not require extensive training. This makes them accessible for various professionals, from engineers to safety officers.

4. Instant Results

Gas detection tubes provide immediate readings, allowing users to take quick action in case of gas leaks or high contamination levels.

5. No Power Source Required

Since they operate without batteries or electricity, gas detection tubes are ideal for fieldwork, remote locations, and emergency situations.

Common Gases Detected with Gas Detection Tubes

Different gas detection tubes are available for measuring a wide range of gases, including:

- Carbon Monoxide (CO) – Commonly found in industrial emissions and vehicle exhaust.

- Ammonia (NH3) – Used in refrigeration, agriculture, and chemical manufacturing.

- Hydrogen Sulfide (H2S) – Present in petroleum refineries, sewage treatment plants, and mining.

- Chlorine (Cl2) – Found in water treatment facilities and industrial chemical processes.

- Volatile Organic Compounds (VOCs) – Released from paints, solvents, and manufacturing processes.

- Sulfur Dioxide (SO2) – Emitted by power plants, refineries, and volcanic activity.

Applications of Gas Detection Tubes in the UAE

The UAE's industrial landscape demands efficient gas monitoring solutions. Gas detection tubes are widely used in several sectors, including:

1. Oil and Gas Industry

The UAE is a major oil and gas hub, where exposure to toxic gases is a significant concern. Gas detection tubes help detect harmful gases in refineries, offshore drilling platforms, and processing plants.

2. Chemical and Manufacturing Plants

Chemical industries in Dubai, Abu Dhabi, and Sharjah rely on gas detection tubes for regular air quality monitoring to ensure worker safety.

3. Construction and Infrastructure Projects

Large-scale construction projects often involve hazardous gases. Detection tubes are used to monitor confined spaces like tunnels and underground sites.

4. Indoor Air Quality Monitoring

With increasing concerns over indoor air pollution, gas detection tubes assist in assessing air quality in homes, offices, and commercial buildings.

5. Emergency Response and Hazmat Situations

Emergency responders use gas detection tubes for rapid air quality assessment during industrial accidents, gas leaks, or chemical spills.

Factors to Consider When Choosing Gas Detection Tubes

When selecting gas detection tubes in the UAE, consider the following factors:

- Gas Type: Ensure the tube is designed for the specific gas you need to measure.

- Detection Range: Different tubes offer varying sensitivity levels, suitable for low or high gas concentrations.

- Environmental Conditions: Factors like temperature and humidity can impact the accuracy of gas detection.

- Storage and Shelf Life: Gas detection tubes have a limited shelf life. Always check expiration dates before use.

- Pump Compatibility: Ensure the tube is compatible with the gas sampling pump you are using.

Conclusion

Gas detection tubes are an essential tool for air quality monitoring in the UAE. Their simplicity, affordability, and accuracy make them a preferred choice for industries, emergency responders, and environmental monitoring agencies. Whether used in oil refineries, construction sites, or indoor air assessments, these tubes provide an effective solution for detecting harmful gases. By selecting the right gas detection tubes and using them correctly, businesses and individuals can ensure safer working environments and compliance with health and safety regulations.

Amanda Bearse Then & Now!

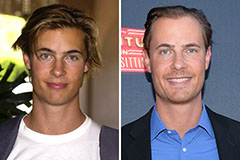

Amanda Bearse Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Robin McGraw Then & Now!

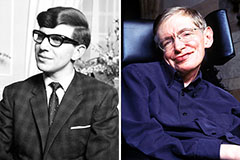

Robin McGraw Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!